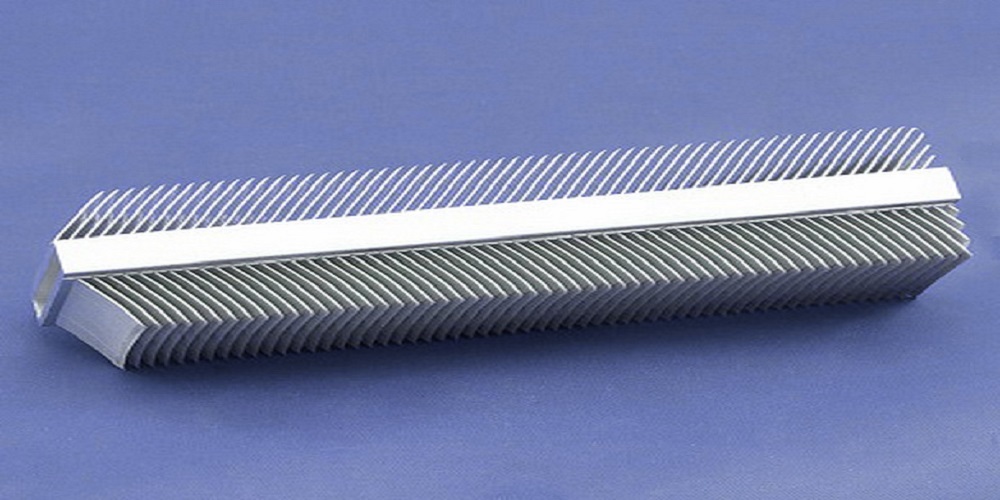

The skived fin is mostly known by skived technology. The mostly skived fin heat sink is manufactured of aluminium or copper materials and usually has a thick fin. These intensity sinks are made of aluminum, copper, or different metals and are intended to build the surface region of the metal in touch with the air. The blades of the skiving heatsink are generally utilized in electronic gadgets to scatter heat produced by the activity of the gadgets.

Advantages of the skived fin heat sink

Lightweight of the skived fin heat sink

The lightweight of the intensity sink decreases the available load of the electronic gadget, which makes it more straightforward to deal with and transport. Skived balance heat sinks are lightweight, contrasting with different intensity sinks.

Low noise

The skived balances disperse heat without the requirement for a fan, which decreases the clamor level of the electronic gadget. Skived blade heat sinks work unobtrusively, contrasted with different intensity sinks.

Good thermal contact

Skived balance heat sinks offer great warm contact with the electronic gadget. The skived balances are clung to a base plate made of a profoundly conductive material, like copper or aluminum. The balances are fastened or brazed to the base plate to guarantee a decent warm association. The base plate gives a low, warm opposition way for the intensity to move from the gadget to the skived balances, which works with effective intensity dissemination.

High performance

Skived balance heat sinks offer elite execution in scattering heat because of their huge surface region. The skived blades are slender and have enormous balances per inch, which expands the surface region of the intensity sink. The expanded surface region gives more space for the intensity to move from the gadget to the air, further developing the intensity dispersal proficiency. This aids in diminishing the working temperature of electronic gadgets, which works on their presentation and lifespan.

The flexible design of skived fin heat sink

Skived balance heat sinks can be planned in different shapes and sizes to suit the particular prerequisites of the application. The skived blades can be set up in various examples to boost the surface region of the intensity sink. The blades can likewise be made in various levels and thicknesses, which permits the intensity sink to be advanced for the particular warm necessities of the gadget. This makes skived balance heat sinks profoundly flexible and versatile to various electronic gadgets.

Improved reliability

Skived blade heat sinks can work on the unwavering quality of electronic gadgets by decreasing their working temperature. High working temperatures can harm electronic parts and lessen their life expectancy. Skived balance heat sinks disseminate heat productively, which diminishes the working temperature of the gadget and expands its unwavering quality and life span.

Environmental friendly

Skived balance heat sinks are harmless to the ecosystem contrasted with different kinds of intensity sinks. Skived balance heat sinks require less material and energy to produce, which decreases their carbon impression. The lightweight of the intensity sink also lessens the energy expected to move it, further decreasing its ecological effect.