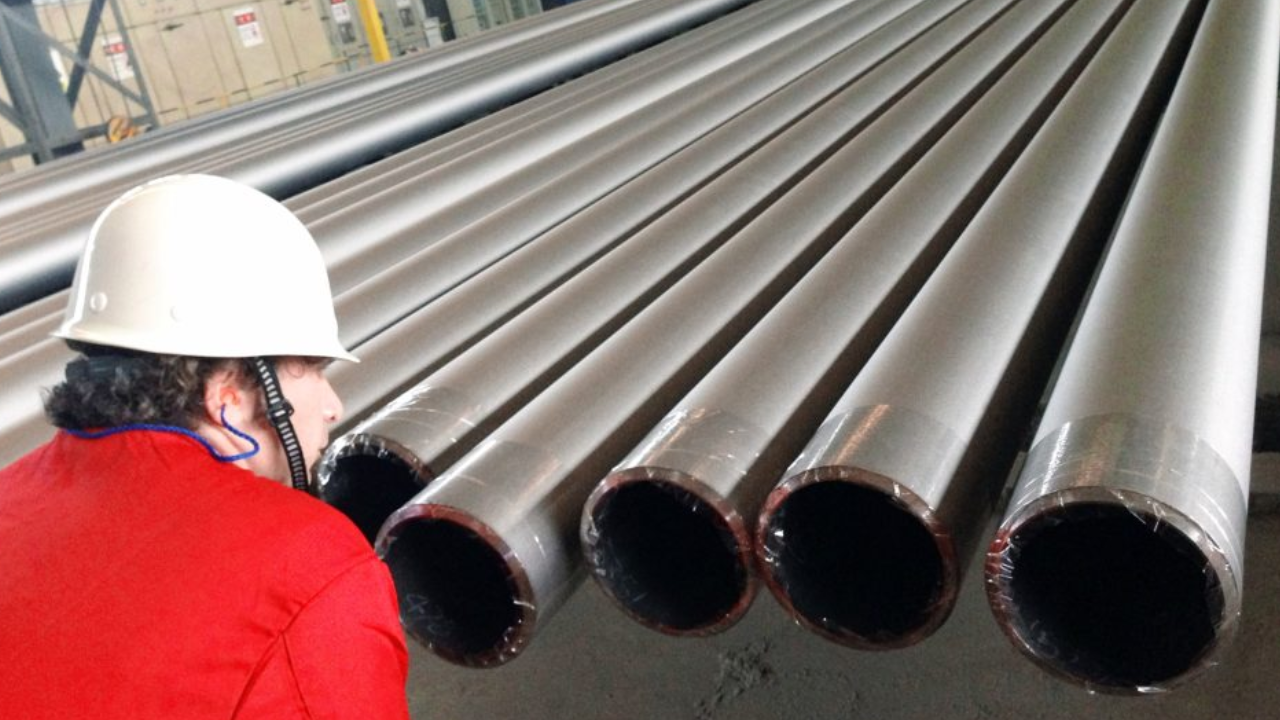

ASTM A53 steel pipes are a cornerstone in the field of steel pipe standards, offering a versatile and dependable solution for a wide range of industrial applications. ASTM International developed the A53 specification, which includes both seamless and welded steel pipes and caters to a wide range of requirements. These pipes are strong and resistant to corrosion, which makes them perfect for harsh environments.

A53 pipes are widely used in vital industries, including oil and gas, water supply, structural engineering, and more. The standard steel pipe a53 has three types. A53 pipes, known for their durability and cost-effectiveness, are frequently galvanized to improve corrosion resistance, making them appropriate for harsh environments. Furthermore, A53 Grade B pipes are favored for applications needing increased strength, notably in structural engineering.

Are A53 Pipes Cost-Effective Compared To Other Steel Pipes?

Yes, ASTM A53 pipes are often regarded as more cost-effective than other steel pipes. Their ubiquitous availability, adaptability, and ease of production all contribute to their affordability. Furthermore, galvanization improves corrosion resistance, potentially lowering maintenance costs over the life of the pipes. However, precise cost concerns may differ depending on project requirements, and when comparing costs, it is best to consider elements such as applicability, durability, and installation.

Applications of ASTM A53 Steel Pipes Across Industries

Steel pipes are critical components in a variety of industrial applications, providing a strong and dependable means of transporting fluids and gases. Among the several steel pipe specifications available, ASTM A53 stands out as a widely utilized and versatile standard. In this article, we’ll look at the various sectors that use ASTM A53 steel pipes, highlighting the distinguishing features that make them a popular choice.

Oil and Gas Industry

The oil and gas industry is one of the most common applications for ASTM A53 steel pipes. These pipes are ideal for delivering oil, gas, and other hydrocarbons due to their endurance and resistance to corrosion. A53 pipes, particularly those galvanized for extra protection, are critical in guaranteeing the integrity of pipelines that travel through difficult terrain and are subjected to a wide range of climatic conditions.

Water Supply and Infrastructure

ASTM A53 steel pipes play an important role in water supply and infrastructure projects, ensuring reliable water distribution systems. Their durability and resistance to corrosion make them suitable for both underground and above-ground applications. Municipalities and water treatment facilities rely on these pipes to keep water supply networks intact, which contributes to the stability and resilience of vital infrastructure. A53 pipes are an essential component in the design and maintenance of water-related projects around the world.

Automotive and Transportation

In the automotive and transportation sectors, ASTM A53 steel pipes play a crucial role in fabrication. Used for constructing exhaust systems, chassis components, and other structural elements in vehicles, these pipes contribute to the industry’s safety and performance standards. Renowned for their strength and durability, A53 pipes ensure the longevity and reliability of automotive structures, meeting the demanding requirements of diverse operating conditions in the dynamic field of automotive engineering.

Agriculture and Irrigation

ASTM A53 steel pipes are critical in agriculture and irrigation systems for transporting water and fertilizer efficiently. These pipes, valued for their corrosion resistance, provide a long-lasting answer to agricultural issues. A53 pipes help to optimize crop production by making it easier to transport important materials. Their dependability and lifespan make them a cost-effective option for the agricultural business, assisting it in increasing productivity and sustainability.

Renewable Energy Infrastructure

ASTM A53 steel pipes are essential components in renewable energy systems. These pipes help to build support structures, foundations, and electrical conduits for solar and wind-generating plants. A53 pipes, known for their durability and strength, play an important part in assuring the longevity and reliability of renewable energy installations, thereby contributing to the global shift to sustainable and environmentally friendly energy solutions.

Mechanical and HVAC Systems

Mechanical and HVAC system manufacturers rely on ASTM A53 steel pipes for ducting and plumbing. The pipes’ weldability and ability to endure temperature changes make them ideal for transporting air, steam, and other gases throughout these systems. A53 pipes improve the efficiency and dependability of mechanical and HVAC installations in both industrial and commercial settings.

Summary

ASTM A53 steel pipes are adaptable and widely used in a variety of sectors. Their durability, strength, and corrosion resistance make them ideal for crucial applications ranging from oil and gas transportation to structural engineering and renewable energy projects. As industries expand, the significance of A53 pipes in meeting different infrastructure needs is anticipated to remain substantial, highlighting their long-term relevance in the area of steel pipe applications.